No products in the cart.

TECAIRE is specialist in industrial equipment in the processing of coffee and cocoa industry from reception of bulk material up to packaging since 1978. El 95% of the production of TECAIRE is destined for international markets with more than 300 installation in more than 25 countries in 5 continents.

Product range

NATURAL/REGULAR COFFEE ROASTERS

- Drum roaster with capacities from 60 to 600 Kg of green coffee per batch

- Productions from 120 to 3.000 Kg hour of roasted coffee

- Furnace equipped with electronic & progressive gas or diesel burners, low emissions

- Uncovered circular cooler. Covered circular coffee (double aspiration system)

- Chaff collection cyclone

- Control panel with PLC and color touch screen SIEMENS / AB

- Pre-heating system for green coffee

- Afterburner with or without catalyst

TORREFACTO/SUGAR-COATED COFFEE ROASTERS

- Capacities from 60 to 500 Kg of green coffee per batch. Double or single roasting drum

- Productions from 180 to 1.800 Kg hour of torrefacto coffee

- Furnace equipped with electronic & progressive gas or diesel burners, low emissions

- Cylindrical coffee with dosing device

- Chaff collector cyclone

- Control panel with PLC and color touch screen SIEMENS / AB

- Afterburner with or without catalyst

LOADING, CLEANING AND STOCKING OF GREEN COFFEE

- Loading of green coffee in three different formats: bulk, big bags and standard bags

- Pneumatic ad mechanical conveyors

- Silos of cylindrical, cubic or octagonal configuration

- Capacities ranging from 4 TN up to 500 TN

- Volumetric and densimetric green coffee cleaning systems

- Feeder to roasting section ordered by origin or by blends

- Control panel with PLC and color touch screen SIEMENS / AB

LOADING, CLEANING AND STOCKING OF ROASTED COFFEE

- Loading of roasted coffee from coffee roasters

- Vacuum destoner for roasted coffee

- Silos of cylindrical, cubic or octagonal configuration

- Degassing for natural and torrefacto coffee

- Blender for roasted coffee, in order to blend different origins

- Conveyors up to grinding section or up to packaging section

- Control panel with PLC and color touch screen, SIEMENS / AB

LOADING, CLEANING AND STOCKING OF GROUND COFFEE

- Loading of coffee from the grinding section

- Pneumatic or mechanical conveyors up to degassing battery

- Natural and homogeneous degassing, without internal forced movement of coffee (First In, First Out)

- Cube-shaped silos, in order to standardise the coffee density

- Conveyor to the packaging section by pneumatic or mechanical transports

- Control panel with PLC and colour touch screen, SIEMENS / AB

GRINDERS FOR COFFEE

- Disks and cylinder grinders for coffee

- Capacities from 200 to 2.000 kg/hour

- Efficient cooling system during grinding

- Different grinding qualities (mesh number), from filter to Turkish

- Silent, continuous and homogeneous operational

ENVIRONMENTAL QUALITY

- Post-combustion system for the air of roasting

- Catalysts for the treatment of hot air

- Recycling of energy through recycling-energy saving

- Chaff compacting – pelleteizers

- Settling of solid particles of the cooling system

- Online analysis of emissions

- Low consumption electrical equipment

- Laboratory equipment for green, roasted and ground coffee

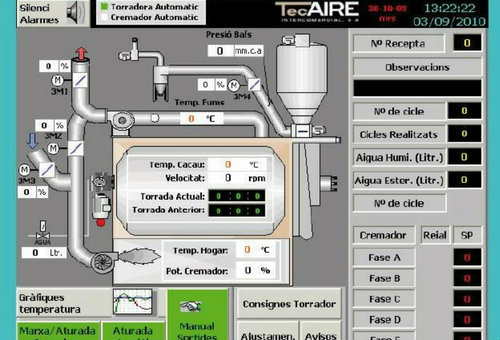

PROCESS CONTROL SYSTEM

- Cabins for the warning, revision and correction of data from the operational parameters of each processing section

- Support for management software for quality standards – ISO, IFS

- SIEMENS / AB software

- Control of safety systems

Tiếng Việt

Tiếng Việt