No products in the cart.

Rotex Global is a manufacturer of dry-separation screening equipment with over 170 years of experience serving the needs of worldwide processing industries.

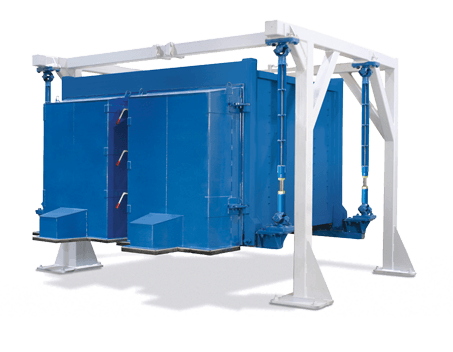

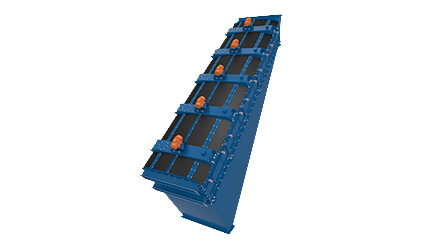

Rotex Screeners provide unusually high efficiency and capacity because they have a unique gyratory-reciprocating motion of the near-horizontal screen surface, combined with a positive screen mesh cleaning system.

Gyratory Reciprocating Motion

Gyratory motion rapidly distributes, stratifies and separates. This unique gyratory motion pattern imparts a combination of actions to the material as it passes along the screen surface. It begins with a horizontal circular motion at the feed end, gradually diminishing along the length of the machine to an elliptical path, and finally to an approximate straight-line motion at the discharge end. There is no vertical component to this motion – thus keeping the material in constant contact with the screen surface.

1. DISTRIBUTES: Circular Motion at the Feed

The gyratory motion at the feed side of the machine immediately spreads the material across the full width of the screen surface to maximise screen utilisation. At the same time, this motion stratifies the material, causing the fines to sink down against the screen surface. The particles that are appreciably smaller than the openings, quickly pass through at this part of the screen.

- Spreads the material across the full width of the screen surface

- Stratifies the material

- Aggressively conveys material forward

2. STRATIFIES: Changing to Elliptical Motion at Centre

As the circular motion diminishes into an elliptical path, the gentle near-horizontal motion causes the fine particles closer in size to the screen mesh – the near-size particles – to fall through the mesh openings.

- Long-stroke elliptical action

- Enhances product stratification

- Conveys material at high capacity

3. SEPARATES: Straight-Line Motion at Discharge End

The nearly linear reciprocating motion at the discharge end of the iBulk Rotex Screener removes those particles closest in size to the mesh openings, while gently conveying the oversize material off the screen. In addition, the unique iBulk Rotex ability to advance or retard material flow at the discharge end, allows further separation fine-tuning to achieve the most efficient and accurate motion for the application.

- Removes near-size particles

- Improves screening efficiency

- No vertical component ensures material is in constant contact with the screen surface

Advantages

Eliminates Screen Blinding

Through the use of our mesh cleaning balls and Gyratory Reciprocating Motion, material blinding is virtually nonexistent.

Consistent Screen Tension

The screen is automatically tensioned with each new installation through the use of our unique screen-attachment method.

Longevity and Durability

Rotex drives are designed for long-term, trouble-free service with minimal maintenance.

Increased Screening Performance

All Rotex machines deliver greater efficiencies, superior particle accuracies and higher yields.

PRODUCT OPTIONS

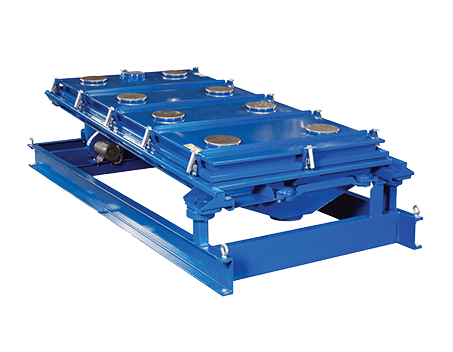

ROTEX®

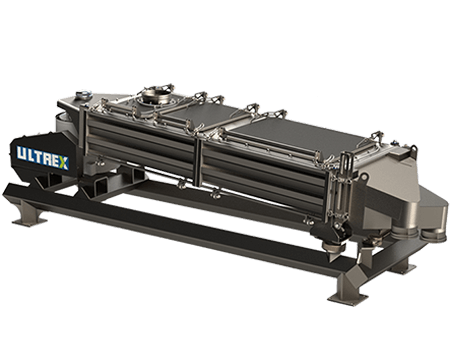

ULTREX™

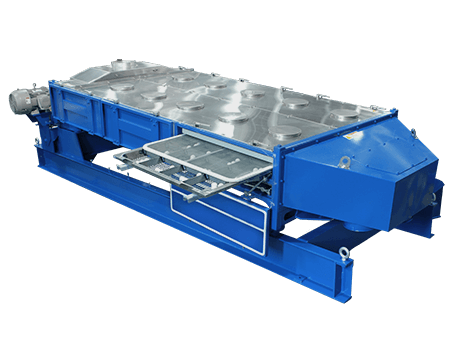

APEX™

Minerals Separator™/MEGATEX XD™

MEGATEX Grain Cleaner™™

ROTEX Direct Drive Feeder™

ROTEX Hi Cline™

ROTEX Plastic Pellet Screener

GRADEX 2000™

Applications and Industries

Rotex Screeners are operating at hundreds of locations, screening literally thousands of different materials. While not all inclusive, the following list details some of the industries and applications where Rotex is the screener of choice.

AGRICULTURE

CORN, WHEAT, SEED CLEANING, SOYBEANS, OILSEEDS, CANOLA / RAPESEEDS, PELLETS, TOBACCO, LENTILS

MINERALS

SALT, FRAC SAND, CERAMIC PROPPANT, BENTONITE, INDUSTRIAL SAND, PETROLEUM COKE, ROOFING GRANULES

CHEMICAL

AMMONIUM SULFATE/NITRATE, CALCIUM HYPOCHLORITE, CATALYST, BATTERIES, DETERGENTS

PLASTICS

ENGINEERED PELLETS, COMMODITY PELLETS, POLYMER SCREENING, POLYMER SCREENING

FOOD

SUGAR, CEREALS, COFFEE , FLOUR, RICE, STARCH, DAIRY POWDERS, CITRIC ACID

FERTILIZER

DAP/MAP, POTASH, UREA, NPK

Tiếng Việt

Tiếng Việt