No products in the cart.

Máy đùn hai trục CTE PLUS | Coperion

| Model No.: | CTE20 CTE35 CTE50 CTE65 CTE75 CTE96 CTE135 CTE165 |

| Thương hiệu: | Coperion |

| Loại trục | Trục vít đôi |

| Năng suất | Min.: 2 kg/h

Max.: 5,000 kg/h |

| Đường kính trục | Min.: 22 mm

Max.: 165 mm |

| Ứng dụng | Compounding |

Category: Máy đùn (Extruder Series)

Máy đùn hai trục CTE PLUS | Coperion

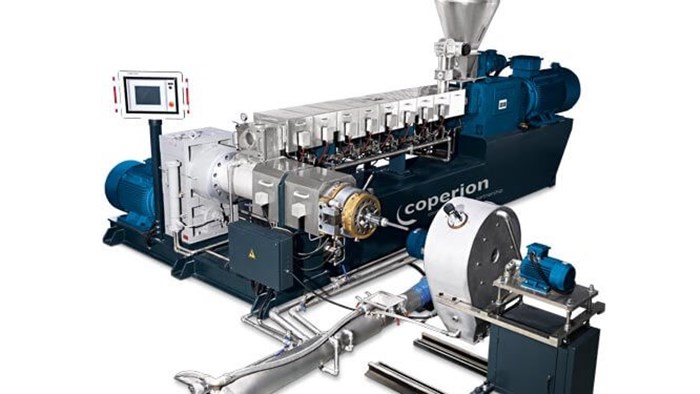

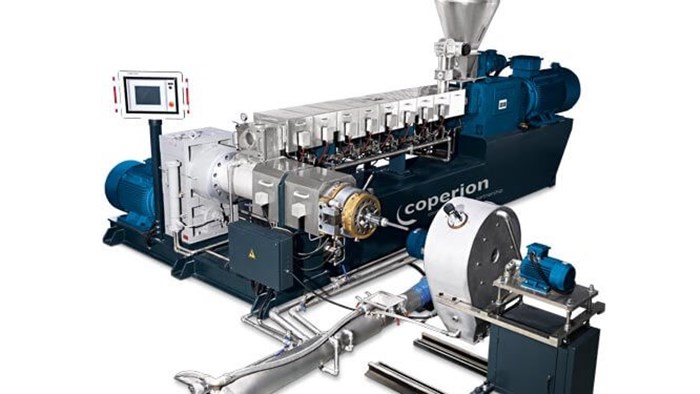

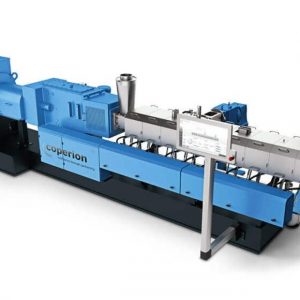

With the CTE PLUS Coperion Nanjing offers a twin screw compounding system with a very attractive cost/performance ratio.

The precise manufacturing of the CTE PLUS series ensures the economical processing of a wide range of applications at high product quality. The CTE PLUS is equipped with a gearbox engineered by Coperion Stuttgart, Germany. It offers a terminal box that meets highest safety standards and is supplied on a unitized base frame at lower cost.

Before delivery each CTE PLUS extrusion system is subjected to a Factory Acceptance Test (FAT) at the Coperion Nanjing site to ensure high quality standards. As an option the CTE PLUS series can be provided with TÜV CE certification. The CTE PLUS series has been developed with a specific focus on the special needs of small and medium-sized companies in China and Asia in terms of technological requirements and price.

CNC machinery with international state-of-the-art equipment, computer controlled machines for grinding of screw parts and for milling of die heads, in-house machining and assembly of gearboxes and our professional quality control are all part of the standards Coperion Nanjing has established to ensure the high reliability of the CTE PLUS compounding systems.

KEY BENEFITS OF THE CTE PLUS SERIES

- Gearboxes, engineered by Coperion, Germany, that can bear a specific torque of 7.2 Nm/cm3 and are exchangeable with old generation CTE gearboxes

- Higher process safety due to new gearbox

- Base frame designed by Coperion, Germany, to ensure higher stiffness

- Gearbox housing manufactured in-house at Coperion Nanjing with CNC machine of Heller, Germany, and checked with 3-dimensional inspection machine of Carl Zeiss, Germany

- Final assembly check with 3-dimensional check instrument of Faro, Switzerland

- Ideal configuration due to modular design

- As flexible as the application – process section according to requirements

- Closely intermeshing, co-rotation twin screws

- Wide range of downstream equipment available

- Before delivery each CTE PLUS extrusion system is subjected to Factory Acceptance Test (FAT) at the Coperion Nanjing site to ensure high quality standards

Related Equipment

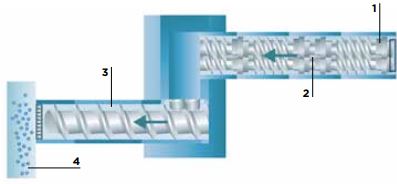

CTE PLUS Two-stage

The CTE PLUS two-stage compounding and pelletizing system is mainly designed for the modification and compounding of heat and shear sensitive materials. Its two-stage set-up and the modular principle of the process section allow highly efficient compounding of applications such as PVC, XLPE and HFFR cable compounds, soft PVC, medical compounds, EVA footwear compounds, etc.

1 Crammer feeder

2 Twin screw extruder CTE PLUS

3 Single discharge screw SE

4 Air cooling pelletizer

WORKING PRINCIPLE OF THE CTE PLUS TWO-STAGE

| Plasticizing, mixing and homogenizing in the twin screw process section |

| Open, pressureless product transfer into the discharge screw with the possibility of degassing |

| Gentle discharge through the die plate with a slow rotating single screw |

| Air-cooling pelletizing as well as eccentric pelletizing – optionally available with strand and waterring pelletizing |

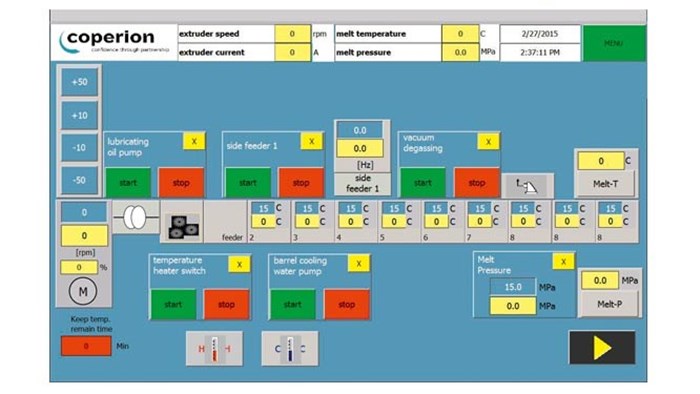

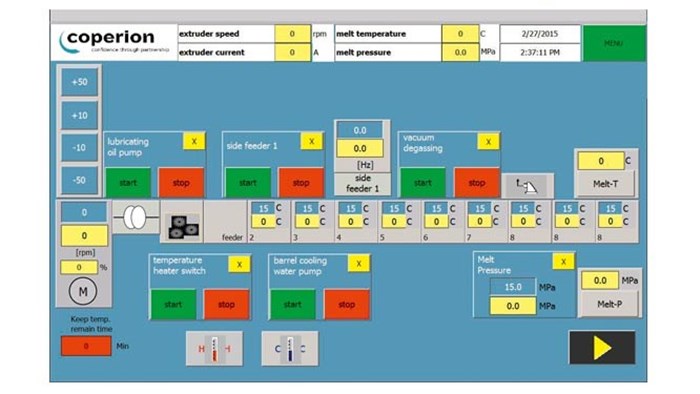

Control Systems for the CTE PLUS Series

- Relay control: Simple, low-cost, but reliable and easy maintenance system

- IPC: System with FCS local bus technology (Profibus, CAN). The functions can be adjusted by software configuration

- PLC: Advanced system using PLC to control the machine. Functions like supervision, alarm, print and parameter tendency can be included

- PCC: PCC system which combines the advantages of a programmable logic controller and industrial computer with DCS technology. The use of a time-sharing multitask operation system allows real time controlling of the complete line

Technical Specification

| Machine size | Torque per shaft (Nm) | Screw diameter (mm) | Screw speed max. (rpm) | Motor power (kW) | Throughput rate (kg/h) |

|---|---|---|---|---|---|

| CTE 20 PLUS | 24 | 22 | 600 | 3 | 2-10 |

| CTE 35 PLUS | 140 | 36 | 600 | 18,5 | 30-70 |

| CTE 50 PLUS | 430 | 51 | 600 | 55 | 90-220 |

| CTE 65 PLUS | 710 | 62 | 600 | 90 | 150-360 |

| CTE 75 PLUS | 1,270 | 71 | 600 | 160 | 260-650 |

| CTE 96 PLUS | 2,500 | 94 | 600 | 315 | 500-1,300 |

| CTE 135 PLUS | 7,160 | 132 | 400/600 | 600/900 | 1,400-3,500 |

| CTE 165 PLUS | 14,300 | 165 | 400 | 1,200 | 2,000-5,000 |

| Machine size | Model | Screw diameter (mm) | Screw speed max. (rpm) | Motor power (kW) | Throughput rate (kg/h) |

|---|---|---|---|---|---|

| CTE 50-120 PLUS two-stage | CTE 50 PLUS | 51 | 400/500/600 | 37-55 | 100-300 |

| SE 120 | 100 | 60/85 | 18,5-22 | ||

| CTE 65-150 PLUS two-stage | CTE 65 PLUS | 62 | 400/500/600 | 55-90 | 150-500 |

| SE 150 | 150 | 60/85 | 37-45 | ||

| CTE 75-180 PLUS two-stage | CTE 75 PLUS | 71 | 400/500/600 | 110-160 | 300-900 |

| SE 180 | 180 | 60/85 | 45-55 | ||

| CTE 96-200 PLUS two-stage | CTE 96 PLUS | 94 | 400/500/600 | 220-315 | 600-1,800 |

| SE 200 | 200 | 60/85 | 55-75 |

Application

- Engineering plastics

- Masterbatch

- Filling

- TPE/TPR/TPV

- Wood composites

- Cable compounds (PVC, HFFR, XLPE, semi-conductive)

- Devolatilization/degassing & reaction

- Direct extrusion

Contact

For more information feel free to contact us as follow:

Mr. Vương: (+84) 356186709 – Email: vuong.nguyen@namtienthinh.com.vn

Be the first to review “Máy đùn hai trục CTE PLUS | Coperion” Cancel reply

Related products

Máy đùn (Extruder Series)

English

English

Reviews

There are no reviews yet.