No products in the cart.

SIDEMEKI X-RAY – FOR TALL FOOD PRODUCTS

SIDEMEKI™ delivers the best value X-ray quality control for tall packages, both liquids and solid foods alike. This inspection system brings a new approach changing the existing standards towards true pack-for-pack traceability. This trend towards primary packaging inspection is now available for side-view applications, such as PET bottles and containers.

The SIDEMEKI™ system is designed for production lines where the food is in packages that are taller than wider, such as bottles, cartons, containers and cans. Ensuring smooth production flow is essential with these packaging types setting a higher expectation for the design of the inspection equipment.

That’s why SIDEMEKI™ is completely lead curtain-free X-ray system, equipped with secure product guides ensuring the food packages transfer effortlessly through, the system is also equipped with various sensors that monitor the system and its functionalities, making SIDEMEKI truly self- monitoring Critical Control Point.

SIDEMEKI™ is the only quality control solution offering food producers a choice to select one or two X-ray generators based on the exact need for the product inspection. With tall products, this means that the system always has the needed inspection accuracy necessary for foreign object detection and specific quality functions, e.g. headspace, fill level, and cap inspection. This equals the best value in the industry.

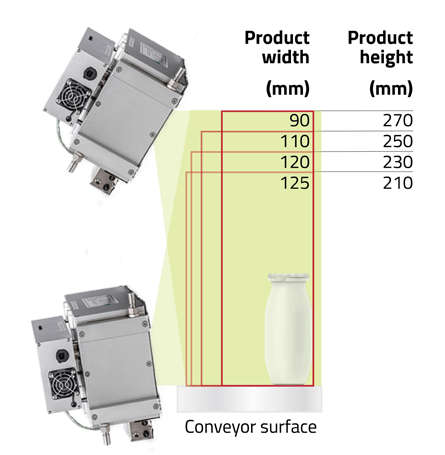

- DETECTION AREA:

Inspected product must fit completely inside the detection area.

Technical specification

| Detection area (W x H) | 90 x 270mm Up to 125 x 210mm* |

| Conveyor speed | Up to 1.0 m/s Option to 1.3 m/s |

| X-ray/detector quantity | 1 or 2 X-ray generators and detectors paired |

| X-ray power | 2 200W / each X-ray generator |

| X-ray leakage | less than 1 µSv/h |

| Detector | Linear scanner, resolution 0.4 mm |

| Software | Mekitec X-ray inspection System SW |

| Operating system | Windows 10 |

| Connectivity | USB, Ethernet |

| HMI | 15” Color TFT LCD Screen |

| Operation Temperature | 0–35° C ambient |

| Cooling | Optional air conditioner** |

| IP rating | IP65*** |

| Relative humidity | 30-85%, non-condensing |

| System power supply | 110/240 VAC, 50–60 Hz |

| Dimensions (W x D x H) | 3343 x 1179-1463 x 1906-2216mm |

| Weight | 735kg |

| Material | Stainless steel, brushed |

| Reject options | 1 or 2 rejecters, air reject or pusher with bins |

| System conveyor | EU and FDA food use approved conveyor belt |

| Radiation protection | Meets EN 61010-02-091, FDA CFR 21 part 1020, 40 |

| Safety system | Safety Circuit CAT 3, Performance Level PL D |

| In-feed/out-feed options |

Two integrated in-/outfeed conveyor options; enables end-feed and side-feed product flow |

*May require additional shrouds for infeed and outfeed depending on the inspected product.

**External circuit IP 34, Internal circuit IP 54. Requires the use of washing covers for air intake.

***Requires the use of washing covers for air intake

Application

BAKERY

CONFECTIONERY

DAIRY

FROZEN FOOD

FRUITS & VEGETABLE

HEALTH & NUTRITION

LIQUIDS

MEATS & SEAFOOD

PET FOOD

DRY BULK & POWDER

READY-TO-EAT

SNACK

Contact

For more information feel free to contact us as follow:

Mr. Vương: (+84) 356186709 – Email: vuong.nguyen@namtienthinh.com.vn

RELATED PRODUCTS

Be the first to review “SIDEMEKI X-RAY – FOR TALL FOOD PRODUCTS” Cancel reply

Related products

MEKITEC X-RAY INSPECTION SYSTEMS

MEKITEC X-RAY INSPECTION SYSTEMS

MEKITEC X-RAY INSPECTION SYSTEMS

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.