No products in the cart.

Coperion

Co-rotating twin screw extruder

Coperion is proud to be a food extrusion system manufacturer with over 130 years of experience and has installed more than 15,000 machines worldwide.

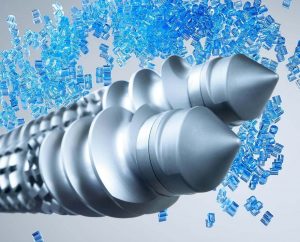

As a pioneer in the development of the closely intermeshing, co-rotating twin screw extruder, Coperion possess unique know-how and an extraordinary wealth of experience in this field with more than 100 technology patents.

COPERION product ranges:

With Coperion you have the partner at your side who can offer you the best solution for all your compounding tasks. This begins with special applications on a laboratory scale and extends right through to industrial production plants.

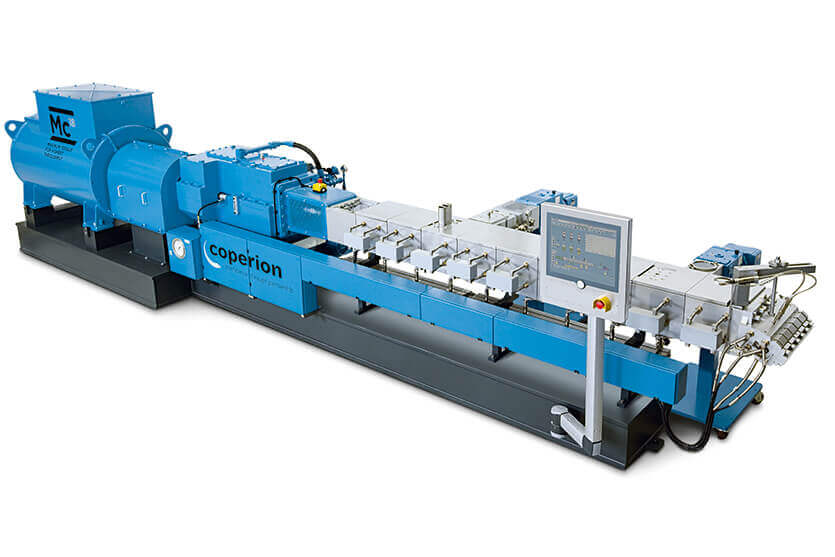

ZSK series

The ZSK series combines the results of more than 50 years of process and processing competence. It is the high-end, high-tech heart of our systems with the maximum torque, speed and free volume.

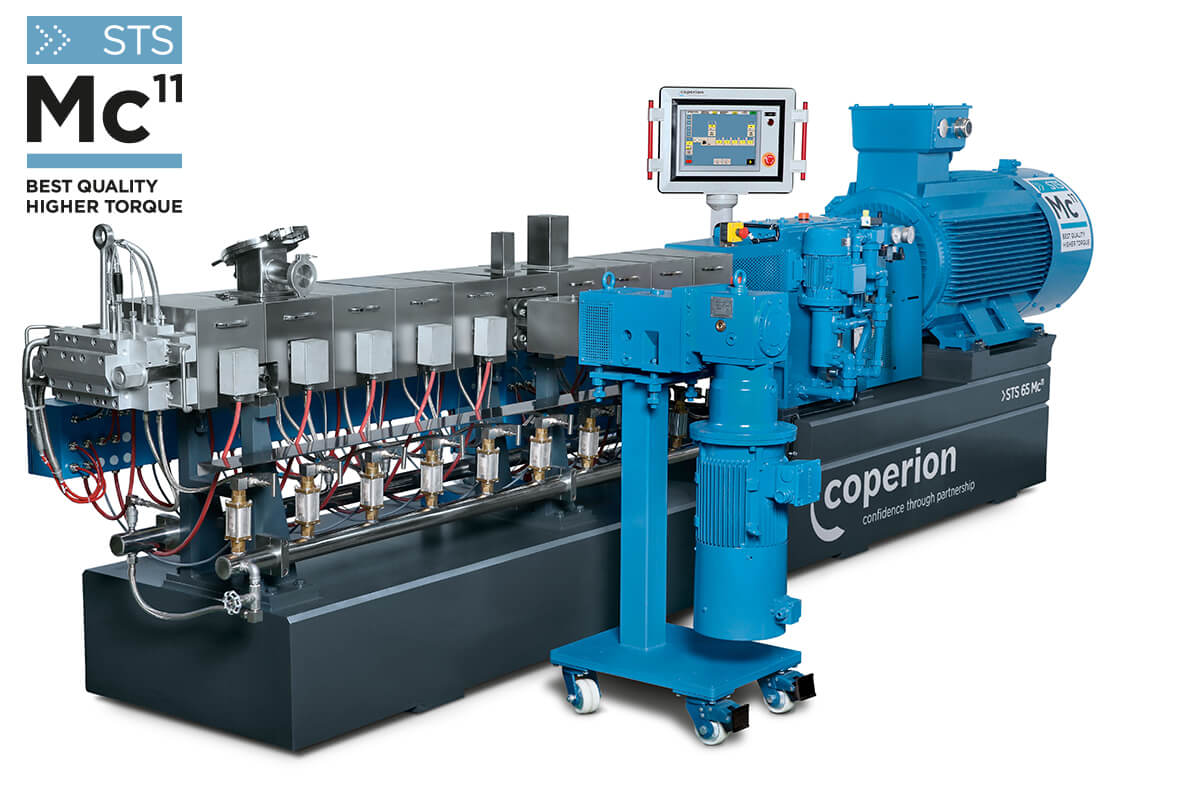

STS series

The STS series features a high degree of standardization and is especially suitable for standardized process tasks. It combines the process technology expertise of Coperion in Germany with the serial production in China at an attractive price-performance ratio. Since the series is certified according to CE standards, it can also be used in Europe.

CTE & CKY series

The CTE and CKY series are developed and produced in China. They are specially adapted to the requirements of the Asian market and have no CE certification.

The differences between three series are shown as below:

| ZSK Mc18 | STS Mc11 | CTE PLUS | |

| Specific torque [Nm/cm3] | 18 | 11.3 | 5.5 (7.2) |

| Max. Screw Speed [rpm] | 1200 | 900 | 600 |

| Output | 600% | 300% | 100% (130%) |

| Torque per shaft | 300% | 200% | 100% (130%) |

| Do/Di | 1.55 | 1.55 | 1.55 |

| Country of Origin | Made in Germany | Made in China | Made in China |

| Engineering | Engineered in Germany | Engineered in Germany | Engineered in China and Germany |

| Gearbox | Made in Europe | Made in Europe | Made in Coperion Nanjing |

| Clutch | Mechanical protection (pneumatic) | Mechanical protection

(disc spring) |

Rupture disc (Nylon pin) |

| Base frame | Profile or welded profile structure, high stiffness | Welded profile structure, high stiffness | Bended metal sheet, welded profile for high torque (7.2) |

| Water manifold | Flexible stainless steel pipe | Flexible stainless steel pipe | Hard connection, copper pipe |

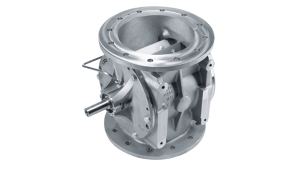

| Side feeder | ZS-B engineered in Germany | ZS-B engineered in Germany | Engineered in China |

| Wiring & Cabling | Multiple-core high temperature resistance cable | Multiple-core high temperature resistance cable | Wires with protection pipe |

| CE Certificate | Yes | Yes (aux. units upon request) | Available under request |

| Application | No limitation | Restricted outside of China | Restricted outside of China |

Applications & Products:

In complex processes such as the compounding of high viscous masses, the quality of the end product is the key factor. From metering, through raw materials feeding, conveying, melting, dispersing, homogenizing, devolatilizing, pressure build-up, filtering and pelletizing, every process step has to be precisely adapted to suit the application. The process and system competence of our specialists guarantees you high-quality results.Each one of our extruders and systems convinces customers with the optimum co-ordination of the individual process steps and gentle handling of the product all at maximum productivity and efficiency.

Tiếng Việt

Tiếng Việt