No products in the cart.

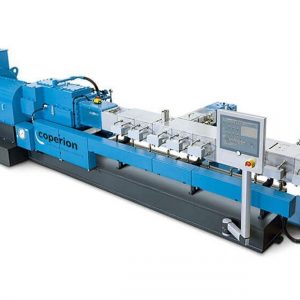

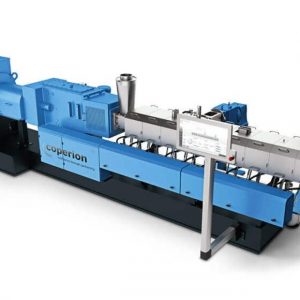

ZSK Mc¹⁸ Twin Screw Extruder | Coperion

| Model No.: | ZSK Series |

| Brand: | Coperion – Germany |

| Number of screws | Twin-screw |

| Other characteristics | High-throughput |

| Screw diameter | Min.: 18 mm

Max.: 133 mm |

| Applications | Compounding |

Category: Extruders & Compounding Machines

ZSK Mc¹⁸ Twin Screw Extruder - Coperion

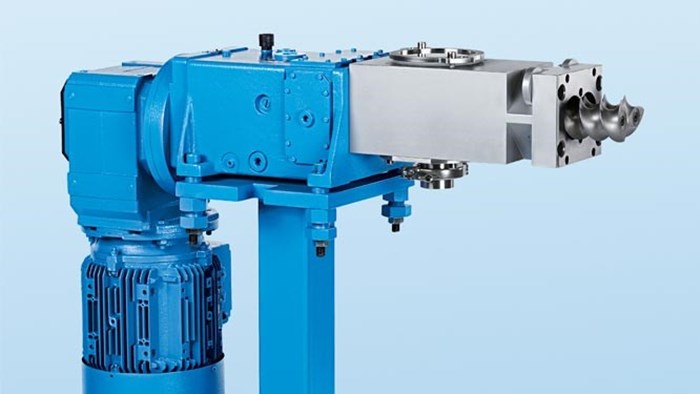

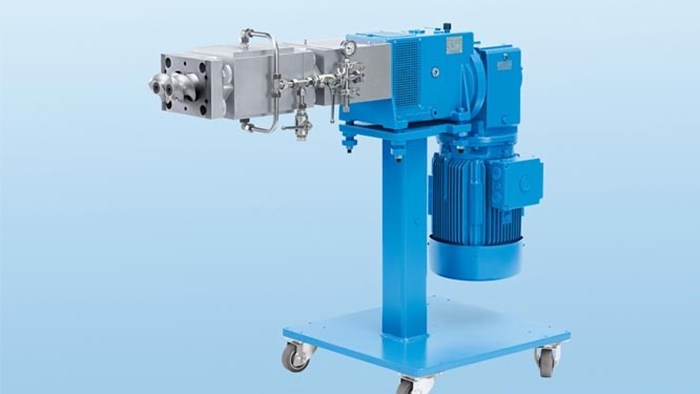

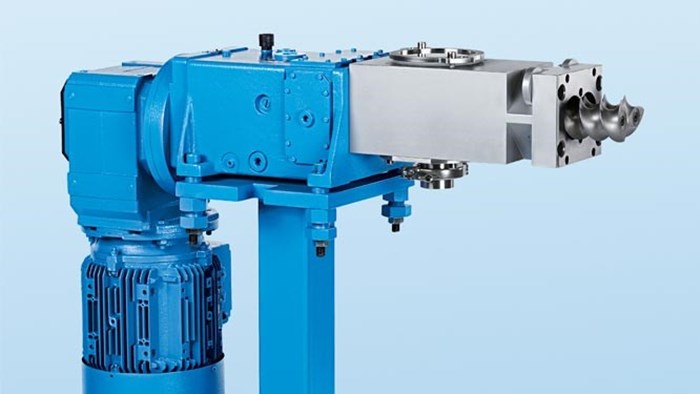

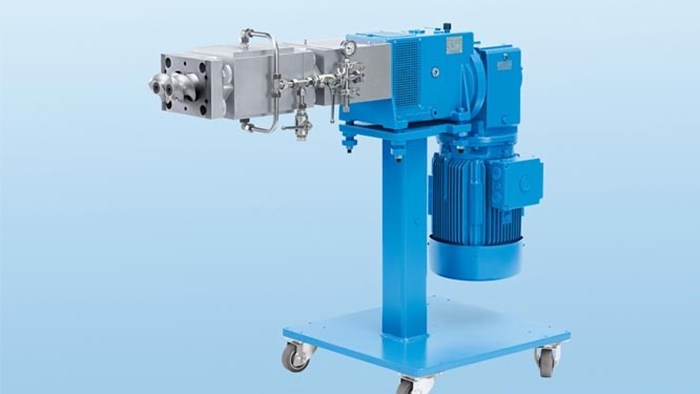

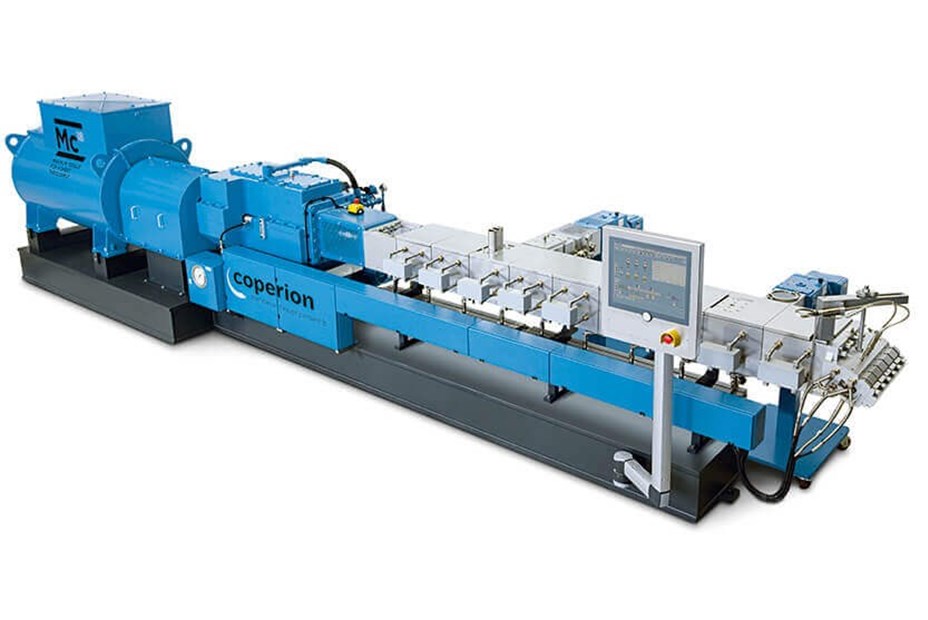

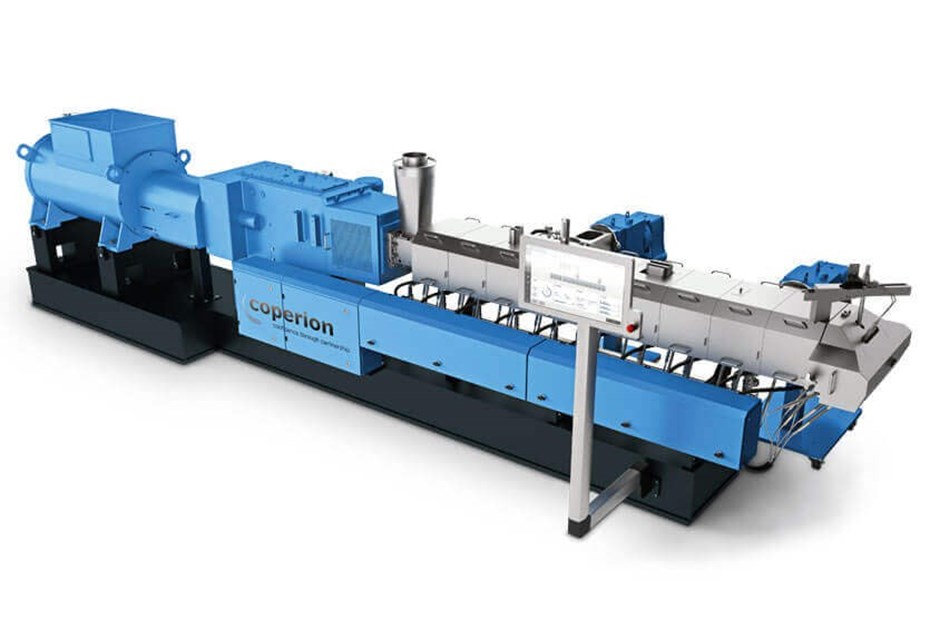

The ZSK Mc18 high performance twin screw extruder is a superlative product. With its torque of 18 Nm/cm3, it has made a name for itself on the market as a throughput champion for products with high torque requirement such as engineering plastics. The 30% increase in torque compared to the predecessor extruder model ZSK Mc PLUS leads to increases in throughput of up to 100%. Therefore the ZSK Mc18 twin screw extruder ensures production with maximum economic efficiency. The optimum price/performance ratio, the extremely energy-efficient operation, the wide range of applications, and the associated high level of flexibility of the machine are additional advantages.

With its Do/Di of 1.55, the ZSK Mc18 strikes just the right balance. It has proven itself in the processing of products with high torque requirements and enables reliable scale-up within the entire Mc18 twin screw extruder series. In addition, it is possible to scale-up and modernize the ZSK Mc PLUS series to the Mc18 series.

KEY BENEFITS OF THE ZSK Mc¹⁸ TWIN SCREW EXTRUDER SERIES

- More than 30% increase of specific torque

- Up to 100% increase in the throughput rate

- Increased energy efficiency by reduced specific energy input

- Greatly improved productivity

- Improved compounding quality by gentle processing with a higher filling degree

- Reduced compound temperature at much greater throughput rates

- Flexible, wide area of applications

- Proven high ZSK safety enabled by new designs and developments

- Gentle product handling for maximum quality

- Maximum flexibility in product changes and machine modifications

- Optimum graduation of the machine sizes

- Excellent mixing behaviour

- Reliable scale-up

- Very wide range of wear protection solutions

- Comprehensive process engineering support

- Flexible solutions for control system

- Comprehensive after-sales services by worldwide Coperion service network

- Large number of application-specific solutions to increase throughput and productivity, e.g. quick-release features, side devolatilization ZS-EG, Feed Enhancement Technology (FET)

Related Equipment

Feed Enhancement Technology (FET)

For significantly increased feeding capacity

Side Devolatilization Unit ZS-EG

For increased throughput rates of up to 30% and improved product quality

Side Feeder ZS-B

Side feeding of fillers and additives in powder or pellet form or cut glass fibers into the process section

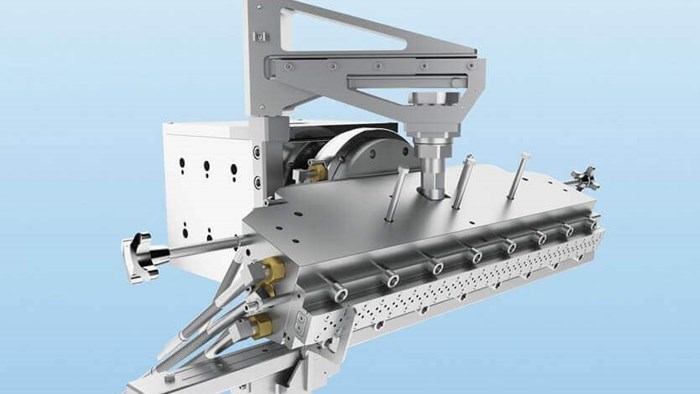

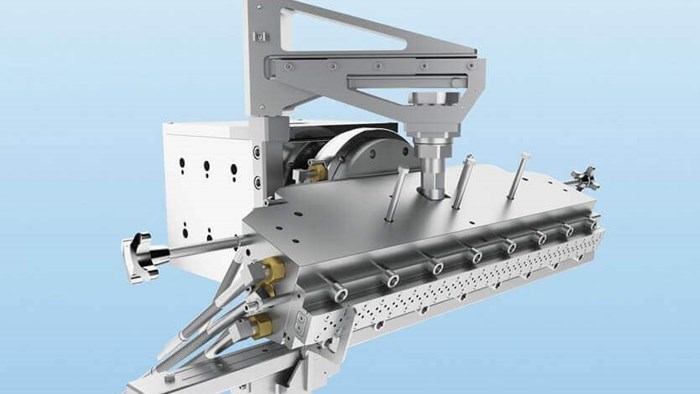

Die Head

Ensures highest throughputs with gentle product handling and maximum heat transfer

Control Systems

User-friendly solutions for the controlling of twin screw extruders

Wear and corrosion resistant solutions

Wear protection for screw elements and barrels

Coperion K-tron Feeders

Smart feeding solutions

Pelletizers

Adapted exactly to Coperion’s extrusion and compounding systems

Quick-release clamps at feed hopper, degassing dome and atmospheric venting

For quick and easy cleaning with quick-release clamps

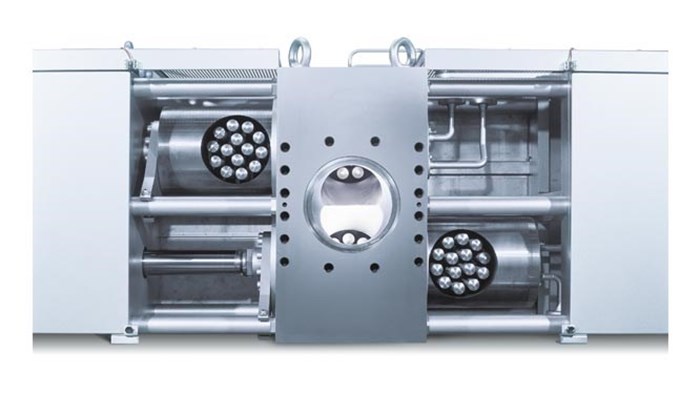

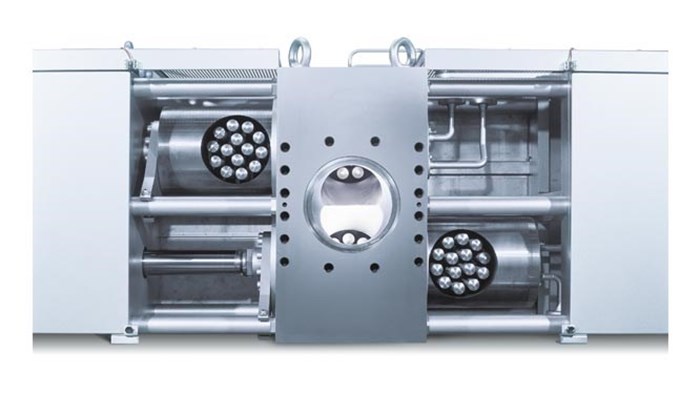

Screen Pack Changer SWZ

Ensures the maximum productivity of your compounding plant

Melt Pump MP

It ensures the necessary pressure build-up for the melt filtration and pelletizing at a very low introduction of energy

Coperion ServiceBox

An integrated system for the online monitoring and logging of faults to ensure trouble-free compounding with stable product quality

Technical Specification

| ZSK | Max. torque per shaft [Nm] |

Specific torque Md/a³ [Nm/cm³] |

Max. screw speed [min⁻¹] |

Max. motor power N [kW] |

Screw diameter [mm] |

| 18 MEGAlab* | 38 | 11,3 | 1,200 | 10 | 18 |

| 26 Mc18 | 140 | 15 | 1.200 | 37 | 25 |

| 32 Mc18 | 315 | 18 | 1,200 | 83 | 32 |

| 45 Mc18 | 930 | 18 | 1,200 | 245 | 45 |

| 58 Mc18 | 2,000 | 18 | 1,200 | 528 | 58 |

| 70 Mc18 | 3,500 | 18 | 1,200 | 924 | 70 |

| 82 Mc18 | 5,700 | 18 | 1,200 | 1,504 | 83 |

| 92 Mc18 | 7,500 | 17 | 1,000 | 1,649 | 92 |

| 119 Mc18 | 15,300 | 17 | 1,000 | 3,364 | 118 |

| 133 Mc PLUS | 20,000 | 15 | 1,000 | 4,398 | 133 |

* Laboratory extruder

Application

- Continuous processes with high energy consumption

- Processing of all previously torque-limited products such as polyamide with glass, PBT with glass, glass fiber-reinforced polypropylene

- Mixing and dispersing of pigments and additives

- Reinforcement with glass, carbon and other fiber materials

- Degassing of volatile components

- Filling with talcum, calcium carbonate, sawdust or other fillers

- Alloying

- Reactive extrusion

- Chemical reactions such as polymerization, polycondensation and polyaddition

- Direct extrusion

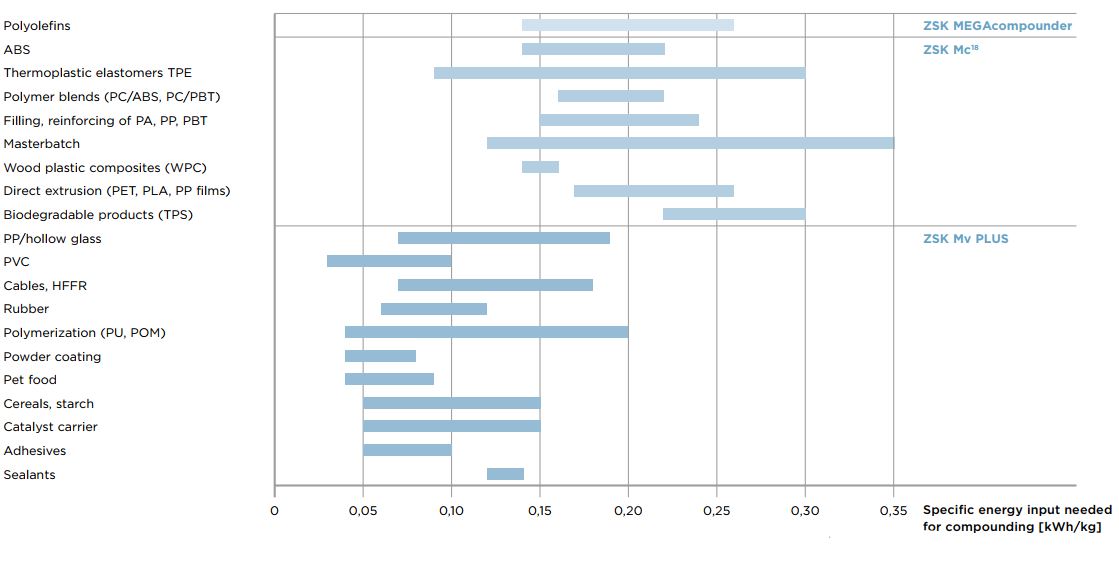

The areas of application of the ZSK twin screw extruder

Contact

For more information feel free to contact us as follow:

Mr. Vương: (+84) 356186709 – Email: vuong.nguyen@namtienthinh.com.vn

Be the first to review “ZSK Mc¹⁸ Twin Screw Extruder | Coperion” Cancel reply

Related products

Extruders & Compounding Machines

Extruders & Compounding Machines

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.